Finding a balance between Design for Manufacture and Patient Considerations

Medical products and packaging, namely pharmaceuticals for this discussion, present unique requirements that can hinder the application of new designs. Conflicts between manufacturing requirements and the needs of the patient who will receive and administer the product are no small matter. In some cases, solely focusing on the patient can lead to over-designing the packaging. This can result in a packaging system that cannot be manufactured at all or one that is cost-prohibitive. What can be done to find the balance?

Design for Patient Needs

Pharmaceutical and biotech packaging design must meet the needs of the end user Designing a solution that ensures proper execution at the point of use must: educate, ensure patient safety, promote compliance, and thus, deliver optimal efficacy of the administered medicine.

Factors that comprise those needs include:

- Dexterity

- Eyesight

- Diagnosis impacts

- Individual conditions (memory, cognition, new requirements replacing old)

- Formulation conditions (frequency of medication, dosing, etc.)

Creating an optimal user experience through interacting with the packaging guides the user from opening the package until they administer the dose and then handle and store the medicine for next use. Providing that instruction calls for packaging engineers to rethink how they design. For example, a set up box system may have previously meant a clinical packaging system with minimal explanation. Today, a set-up box may call for a new delivery system and supplies for in-home use. Again, a medical package design must promote patient compliance, educate with visual cues, and manage dosing and storage. This is just one example of the opportunity for multi-function innovation at the hands of design engineers. Addressing these patient-facing factors is just the beginning. The packaging system must next prove that it can be manufactured to produce the desired user experience at specified production volumes in the selected manufacturing environment.

Design for Manufacturing Realities

Next, let’s back up a step to the common scenario where a pharmaceutical company needs a packaging design for its new drug. We looked at factors considered when designing for the patient; but will those features impact manufacturability?

This article offers a quick view on the value of design for manufacture—and it’s a good transition into the key drivers of the DfM side of the equation:

- Cost

- Scalability

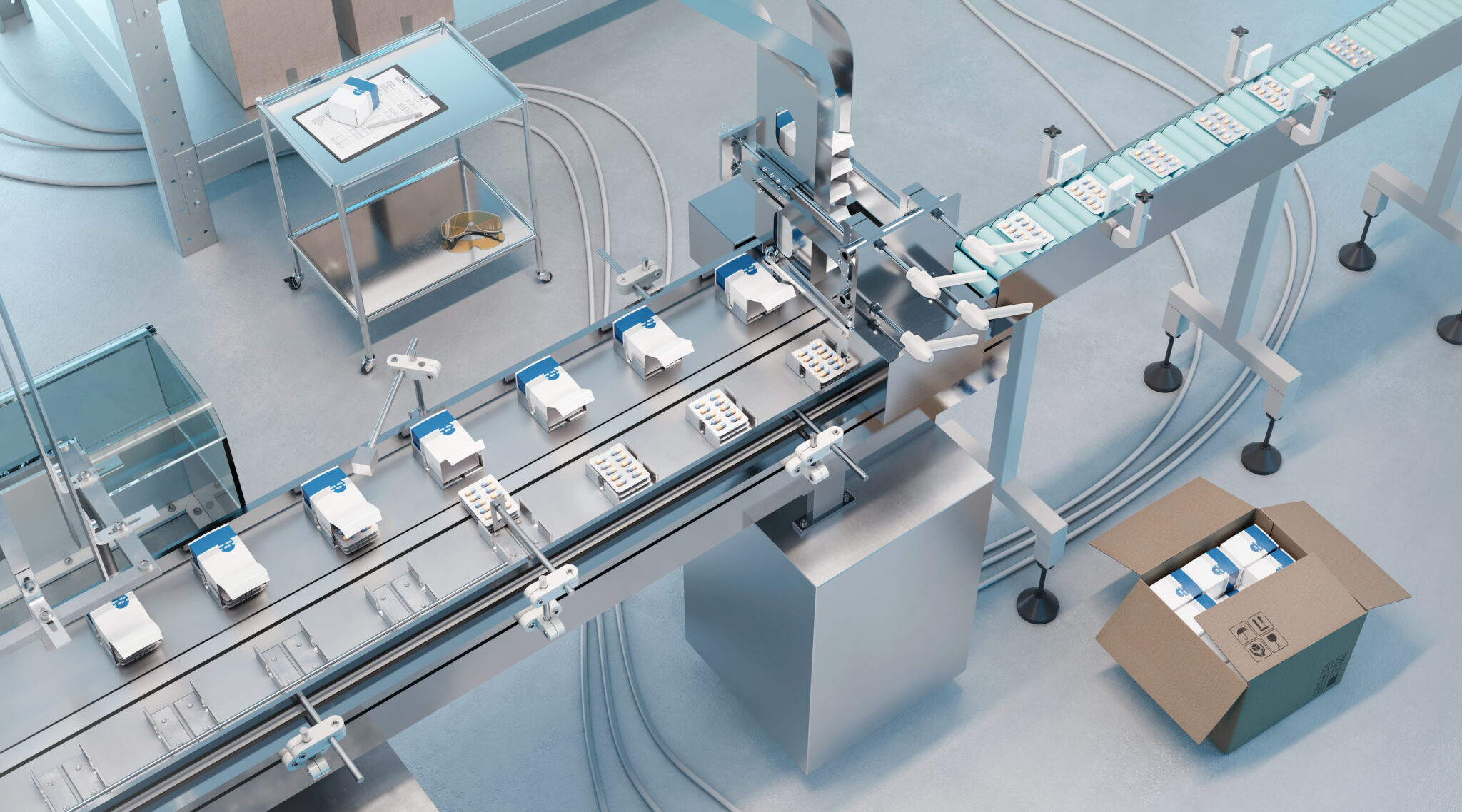

The production line is where potential gaps can emerge to undermine a packaging design prepared without DfM. Costly frustrations are common, even for the best general marketing-brand-design agency. This is because a broad-based branding design firm often lacks commercial manufacturing expertise and industry knowledge. Conversely, a dedicated medical design firm can ask targeted questions that will direct on cost and manufacturability. A pharma-exclusive firm designs across all of these and can also make recommendations when conflicting patient vs. manufacturing needs exist.

It’s worth noting that there are instances where lower volumes (1000s to 100,000) are required. In this case, there is often room for a bit more creativity in the design, because total automation is not a must as it would be for mass-scale production.

It’s when the customer envisions full-scale production DfM that creative license is likely to tighten up. Effective DfM considers tooling cost and may ask the following questions:

- What tray dimensions will work?

- Does the manufacturer have the capabilities to scale that design?

- What is likely to drive up costs here?

- Does it matter more that the patient is able to tear open with a notch or can it be just as efficient as a flap?

Anticipating the challenges the patient demographic may encounter and addressing them in a way that also falls within machine limitations requires experience.

In summary, it is the many components of packaging design that ultimately make something manufacturable (or not). The beauty of a dedicated design firm is the trust and confidence that patient needs will align manufacturing conditions, marrying a packaging design will truly reflect a match made in heaven.