Prototyping: Part of the Design Process

Prototype: a model of a preliminary design concept. Prototypes become the foundation for subsequent design evolutions and allow the designer to test [confirm or deny] assumptions.

Design is an iterative process. I’ve never sketched a design and called it final, which is why I encourage customers to not be afraid of “failure” because it often leads to innovation. Prototyping isn’t just beneficial for customers; it’s beneficial for designers, too. It’s how we prove the feasibility and functionality of our design along the way. Just like many other things in life, time, testing, research, and collaboration all ensure a stronger end product.

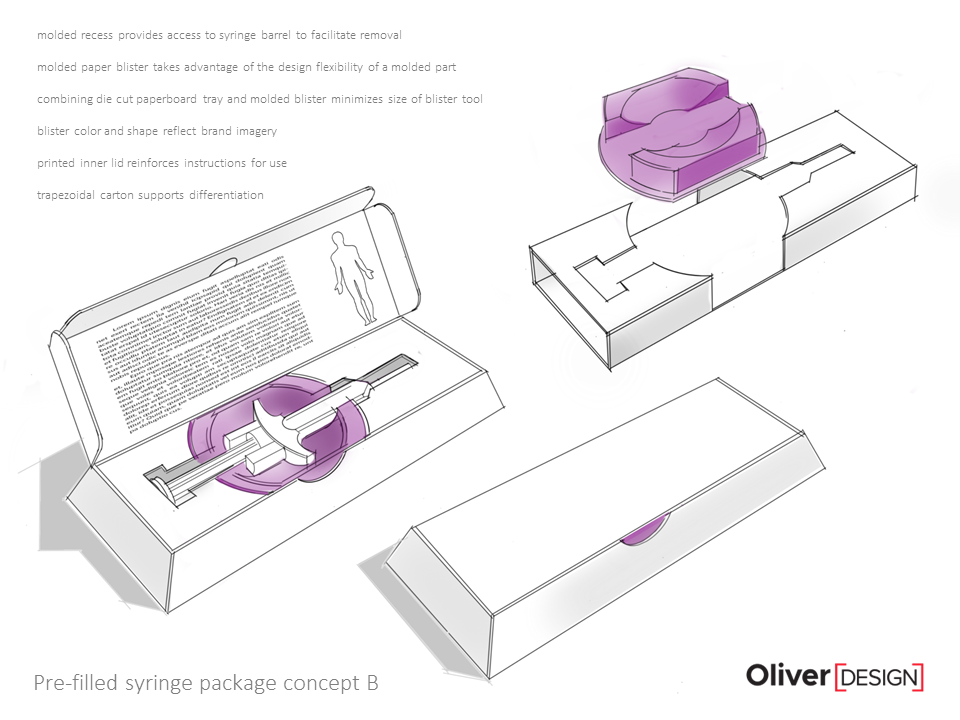

For me, prototyping starts with a simple sketch. It’s an informal and flexible process, but it fuels ideation and is based on informed assumptions. Most importantly, sketching allows the designer to showcase a broad range of options.

Prototyping informs the final design, which is why you should prototype early and often. In my opinion, it’s important to prototype a minimum of three concepts. When a design agency recommends this approach, they’re not upselling you; they’re simply ensuring you have options to choose from. Sometimes a prototype will automatically get discarded for one reason or another, but you never want to be left with a final design by default.

One of the most important aspects of prototyping is using the right materials, process, and construction. They should be the same as what will be used for your final design. 3D printing, while it’s quick and efficient, cannot be used to accurately prototype a final design—it will not provide the same results in testing. This is especially true when it comes to medical and pharmaceutical packaging, which has unique, and often high-risk, specifications and consequences. The quality and accuracy of your prototype pay dividends down the road.

Prototyping can save you time and money. When consumer (or human factors) testing is involved, there is a very high probability that you will be wrong. Why? Because there is always a portion of the decision-making process and rationale you can’t predict or anticipate. Therefore, testing your assumptions is important. Prototyping and testing help avoid having to go back and fix something you’ve discovered late in the process. I’ve seen many instances whereby a customer chooses to skip prototyping and then uncover that a change is needed after operations has the product in-hand, and is ready to produce it. One delay creates a domino effect that can cost a significant amount of time and money. Prototyping helps eliminate this.

Sure, there are all kinds of great designs that can be imagined in packaging. But until you can look at it, handle it, feel it, and try it, there is no context for that design. Prototyping can help with that and enhance performance and ease of manufacturing as well.