Packaging Formats

We design and produce prototypes and sample sets for your application using a variety of packaging formats.

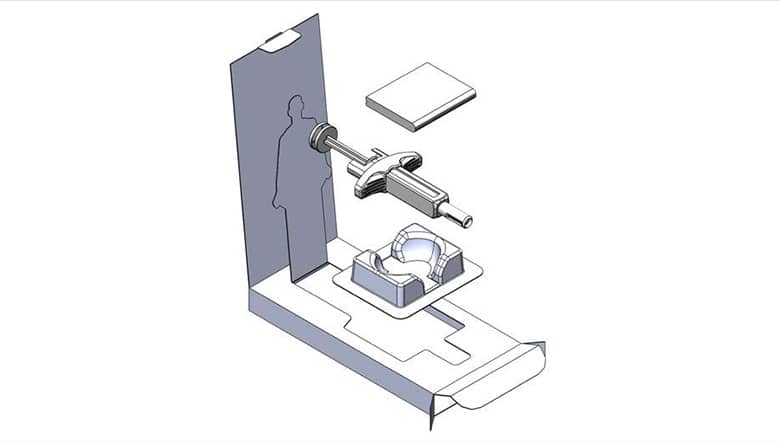

Kits for your therapy can involve a combination of packaging formats. Perfect for both small and large molecule applications, kit design takes into consideration patient conditions and caregiver needs.

Cartons are designed to be patient centric with all design criteria meeting customer scalability requirements which ensures alignment with our design for manufacture principle. We also design with sustainability in mind to help customers reduce their packaging footprint.

Our design team has extensive expertise with thermoform tray designs. In-house tooling enables quick turnaround from concept to tooling fabrication and prototypes. In addition, Oliver Design has IQ/OQ validated production lines that can support customers with various volumes needed from clinical trials to market entries to full commercialization.

Oliver Design’s understanding of a variety of materials and barrier needs ensures the right fit and function for your packaging design. We have the in-house capabilities to produce small runs as well as print on lids.

With quick turnaround times and the ability to offer small volumes for initial testing, cold form and thermoform blisters could be the right packaging solution for your small-molecule therapy that is transitioning from RX to OTC. Custom-designed to incorporate your product specifications as well as child resistant and senior friendly considerations. Read More

Stick-packs offer benefits such as premeasured doses for your therapies. Our stick-pack pouch design capabilities include developing child resistant (CR) opening features and the production representative sample sets needed to complete your CR testing. Read More

With 100% focus on biologics and pharmaceuticals we have a strong understanding of labeling requirements. Printed labels required for human factors studies, marketing and voice of customer (VOC) reviews, and regulatory submissions can all be completed with a quick turnaround.

In-house production of instructions for use (IFU), patient inserts (PI) or quick start guides (QSG) allow for quick turnaround times, perfect for human factors testing where frequent modifications can be accommodated based on participant feedback. IFUs, PIs, and QSGs are made with your unique specifications, including a wafer seal if required.

Our Process

At Oliver Design, we provide support in every stage of the development process.

After the discovery session, Oliver Design will create multiple packaging concept illustrations depicting potential packaging solutions. Concepts are presented as perspective, rough orthographic, and exploded views to communicate assembly and use.

Oliver Design collaborates with the customer to refine the concept illustrations into 1-2 final design concepts.

Needed for fit and function assessments, our prototyping includes producing production representative samples of the refined concept packaging solution.

Related Articles

Packaging on the Move: Balancing Safety and Convenience for Modern Dosage Forms

The Evolution of Child-Resistant Packaging: Protecting the Most Vulnerable

Contact Us